A Guide to FeRFA’s Resin Floor Types & Rating System

Specifying the right type of resin flooring for your commercial or industrial space is critical to ensure effective, long-lasting performance and to stay compliant with regulations. To bring clarity and consistency to the decision, FeRFA (the UK’s Resin Flooring Association) has established a recognised classification system of the different types, their thickness, and common usage.

We’ve written this guide to break down the FeRFA system and support informed decisions about what type of resin flooring your space might need. Alongside a flooring specialist, understanding these classifications will help you specify a system that performs and lasts. Learn more about FeRFA and the different types of resin flooring below.

What Is FeRFA?

FeRFA is the UK’s Resin Flooring Association: the leading authority on resin flooring standards. Representing manufacturers, contractors, and suppliers, FeRFA sets the benchmark for performance and installation quality.

Its classification system is referenced in BS 8204-6, Section 6.2, making it a trusted guide for commercial and industrial flooring specifications. If a resin floor is FeRFA-rated, you can trust it’s been measured against rigorous, industry-approved criteria.

The FeRFA Resin Floor Rating System: Types 1-8

FeRFA classifies resin flooring systems into eight distinct types based on thickness, installation method, and from light duty to very heavy duty. This classification helps contractors, specifiers, and facilities managers select the right system for their operational needs, performance expectations, and compliance requirements.

Here’s your quick guide to each type, with more information below:

| Type | Duty | |

| Type 1 – Floor Seal | 150 μm | Light |

| Type 2 – Floor Coating | 150–300 μm | Light to medium |

| Type 3 – High Build Floor Coating | 300–1,000 μm | Medium |

| Type 4 – Multi-Layer Flooring | >2 mm | Medium to heavy |

| Type 5 – Flow Applied Flooring | 2–3 mm | Medium to heavy |

| Type 6 – Resin Screed Flooring | >4 mm | Medium to heavy |

| Type 7 – Heavy Duty Flowable Flooring | 4–6 mm | Heavy to very heavy |

| Type 8 – Heavy Duty Resin Flooring | >6 mm | Very heavy duty |

FeRFA Type 1 – Floor Seal (Light Duty)

Type 1 floor seals are applied in two or more coats and are generally solvent- or water-borne systems. They are designed to protect and enhance existing substrates rather than provide structural strength.

Floor seals help reduce dusting, improve cleanability, and offer limited resistance to moisture and chemicals.

Typical Uses

Low-traffic areas, plant rooms, storage spaces, and back-of-house zones where protection and appearance are required without heavy mechanical demand.

FeRFA Type 2 – Floor Coating (Light/Medium Duty)

Floor coatings are applied in two or more coats and are generally solvent-free, two-component epoxy or polyurethane systems. They provide a harder-wearing and more decorative finish than floor seals, offering resistance to abrasion, impact, and chemical attack.

Typical Uses

Commonly specified in garages, warehouses, workshops, and light industrial environments where moderate traffic and improved durability are required.

FeRFA Type 3 – High Build Floor Coating (Medium Duty)

High-build floor coatings are thicker, solvent-free systems applied in two or more coats to deliver enhanced durability and chemical resistance. Typically epoxy-based, high-build systems can be applied to new concrete or existing epoxy floors, are available in a wide range of colours, and are often ready for traffic within 24 hours, making them a practical and versatile solution.

Typical Uses

Well-suited to medium-duty industrial and commercial environments. Typical settings include factories, warehouses, and production areas.

FeRFA Type 4 – Multi-Layer Flooring (Medium/Heavy Duty)

Multi-layer flooring systems, often referred to as ‘sandwich’ systems, consist of several layers, including a base coat, aggregate-filled wear layer and protective seal coat. This structure provides improved strength, wear resistance, and protection from dirt, moisture, and other contaminants.

Typical Uses

Type 4 systems are commonly used in environments that require a tougher surface, such as commercial kitchens, wet processing areas, car parks, and industrial walkways.

FeRFA Type 5 – Flow Applied Flooring (Medium/Heavy Duty)

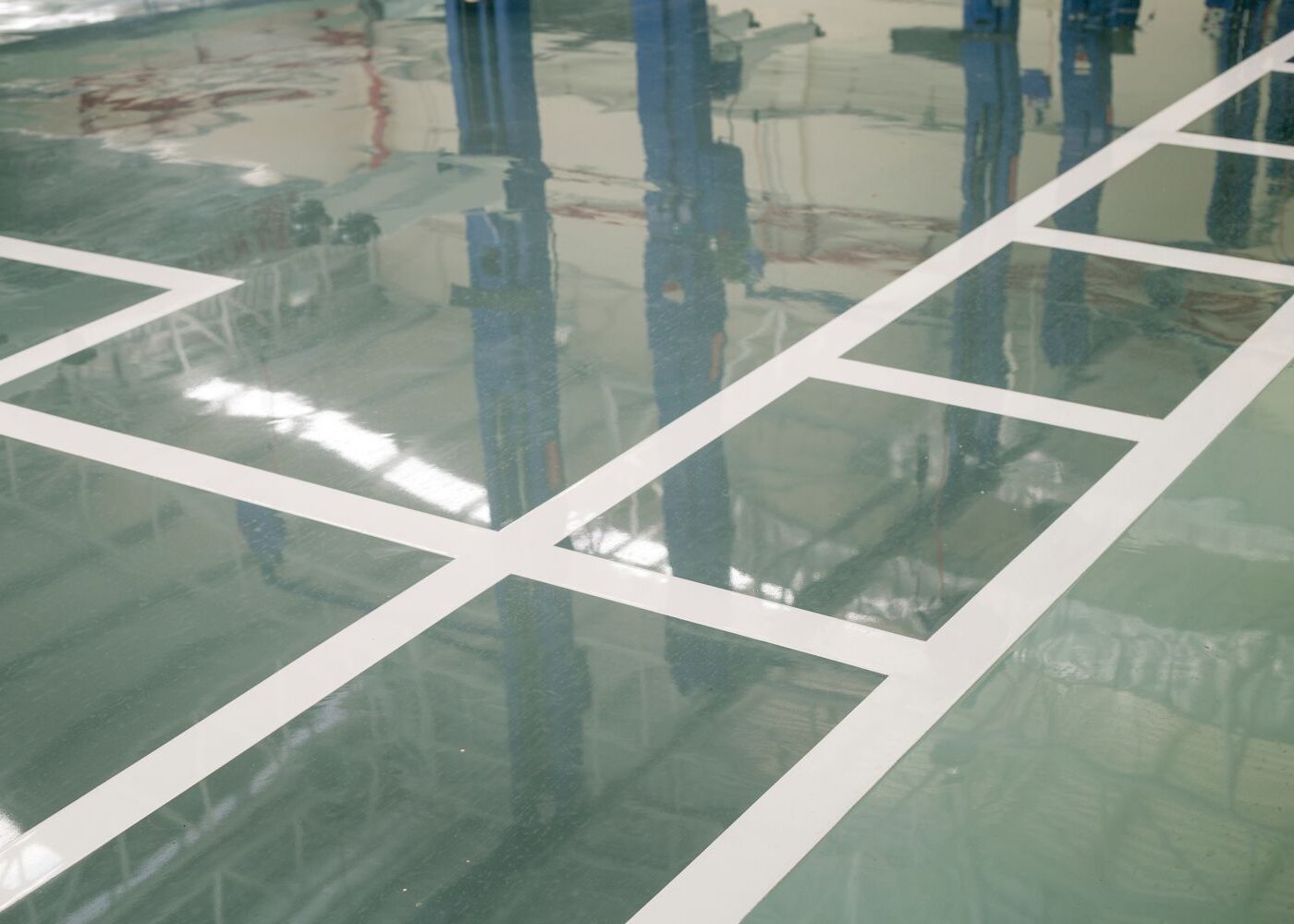

Flow applied flooring, also known as self-smoothing or self-levelling flooring, creates a seamless and smooth surface finish. These two-component systems are resistant to chemicals, oils, and solvents, and are easy to clean and maintain, as well as providing slip resistance.

Typical Uses

Suitable for both wet and dry environments, Type 5 flooring is often used in laboratories, food and beverage production, pharmaceutical facilities, and areas subject to heavy foot traffic or light vehicular movement.

FeRFA Type 6 – Resin Screed Flooring (Medium/Heavy Duty)

Resin screed flooring systems are trowel-finished, heavily filled, and typically incorporate a surface seal coat to minimise porosity. These high-performance systems offer excellent resistance to moisture, abrasion, and impact, while remaining hygienic and easy to clean.

Typical Uses

Type 6 resin screeds are widely specified in warehouses, factories, manufacturing environments, retail spaces, and leisure facilities, where durability and slip resistance are essential.

FeRFA Type 7 – Heavy Duty Flowable Flooring (Heavy/Very Heavy Duty)

Heavy duty flowable flooring systems provide a smooth, seamless surface with significantly increased thickness and strength. Type 7 systems offer a balance between durability and installation efficiency, helping to minimise downtime while delivering long-term performance.

Typical Uses

Designed for demanding industrial and commercial environments, Type 7 resin floors are suitable for areas exposed to heavy traffic, mechanical loading, and chemical or oil spillages.

FeRFA Type 8 – Heavy Duty Resin Flooring (Very Heavy Duty)

Type 8 systems are the most robust category within the FeRFA classification. These trowel-finished, aggregate-filled resin floors are effectively impervious throughout their entire thickness. Designed for longevity, they deliver maximum durability with minimal ongoing maintenance.

Typical Uses

Extremely resistant to impact, abrasion and aggressive chemicals, Type 8 floors are ideal for environments such as heavy engineering, chemical processing, waste facilities, and areas with constant heavy machinery use.

Key Considerations for Specifying Resin Flooring

FeRFA classifications are a great starting point for specifying the correct resin flooring to suit your environment and operational needs, providing a like-for-like comparison of different types.

Understanding this system and considering the following key functions of resin floors can help to guide your decision when specifying new or refurbished resin flooring:

1. Chemical Resistance

- Different resin systems offer varying levels of resistance to chemicals, oils, solvents, and acids.

- Environments such as manufacturing plants, food processing facilities, and laboratories often require enhanced chemical protection to prevent surface degradation and contamination.

2. Slip Resistance

- Slip resistance can be built into resin flooring through textured finishes or aggregate incorporation.

- Commercial and industrial settings with wet, greasy, or high-traffic areas may require a higher level of slip resistance, reflecting both foot traffic and operational processes.

3. Hygiene and Cleanability

- Seamless resin flooring is highly effective in hygiene-critical environments such as food production, pharmaceuticals, and healthcare.

- These systems are laid without joints or grout lines, preventing dirt and bacteria build-up.

- Systems can also incorporate anti-microbial properties to support strict hygiene standards and easy cleaning regimes.

4. Aesthetic and Design Requirements

- Colour, finish, and decorative options such as zoning markings can enhance appearance, support wayfinding, and reinforce brand identity.

- This is particularly valuable in commercial, retail, and customer-facing spaces where presentation matters.

5. Moisture Tolerance and Substrate Preparation

- Successful resin flooring installations depend heavily on correct substrate preparation and moisture management.

- Excess moisture within concrete can lead to adhesion failure if not properly assessed and addressed.

- Moisture-tolerant systems and thorough preparation ensure long-term performance and durability.

The Role of a Trusted Resin Flooring Installer

Even the highest quality resin flooring system can underperform if it’s not installed correctly. That’s why choosing a specialist contractor who clearly understands the FeRFA classification system and its application in real-world settings is essential.

Concrete Flooring Solutions can support you by ensuring:

- Compliance with industry regulations and safety requirements.

- Performance that matches your space’s operational needs.

- Correct installation, including expert substrate preparation and long-term aftercare.

We’re the UK’s only specialist in both resin and concrete flooring, offering a complete, end-to-end solution. With over 180,000m² installed annually across industrial, commercial, and public sector sites, our team brings the experience, technical insight, and reliability your project demands.

Guiding Your Resin Flooring Needs

Resin flooring types are not only guided by budget, but also by matching the right product to the right environment. The FeFRA classification system is there to provide a clear, standardised framework to support the decision-making process, helping contractors, specifiers, and facilities managers make informed judgements.

By aligning your specification with FeRFA standards and partnering with a supplier who does the same, you ensure greater clarity, performance, and professionalism from the ground up. If you need help choosing the right resin floor type for your industrial or commercial space, our expert team can guide you to the best-fit solution. Get in touch with us today for more information.